- Time:2023/08/18 Posted:Dongguan prospect hardware accessories co.,ltd

DIN7981 self-tapping screws have emerged as a game-changer in the field of assembly. These innovative screws offer a host of benefits that greatly improve efficiency throughout the assembly process. From their unique design to their ease of use, DIN7981 self-tapping screws have become an indispensable tool for industries worldwide.

1. The Advantages of DIN7981 Self-Tapping Screws

DIN7981 self-tapping screws offer several advantages over traditional screws, making them an attractive choice for assembly processes. Firstly, these screws have a pre-drilling ability, eliminating the need for pilot holes. This feature not only saves time but also reduces the risk of damaging the surrounding materials. Additionally, DIN7981 self-tapping screws create their own threads as they are driven into the material, providing excellent grip and stability.

2. Enhanced Efficiency in Assembly

The use of DIN7981 self-tapping screws significantly improves the efficiency of assembly processes. With traditional screws, the time-consuming task of drilling pilot holes can often lead to a delay in the overall production timeline. However, DIN7981 self-tapping screws eliminate this step, allowing for faster and more streamlined assembly. Their ability to create their own threads also ensures a secure and reliable connection, reducing the need for additional reinforcement.

Furthermore, these self-tapping screws offer versatility in terms of the materials they can be used on. They can effectively penetrate various materials including wood, plastic, and metal, making them suitable for a wide range of assembly applications. This versatility not only saves time but also simplifies the procurement process by reducing the need for multiple types of screws.

3. Other Benefits and Considerations

In addition to their efficiency, DIN7981 self-tapping screws also provide other benefits. Their self-drilling capability reduces operator fatigue and the risk of injuries associated with manual drilling. Moreover, their strong grip and resistance to loosening make them highly reliable, contributing to the overall quality and durability of the assembled product.

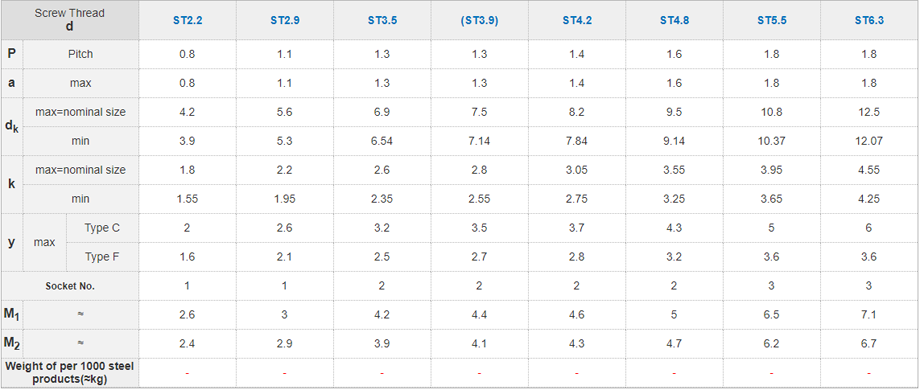

However, it is important to consider certain factors when using DIN7981 self-tapping screws. The correct size and thread type must be selected to ensure a proper fit and maximum efficiency. Additionally, proper torque control during installation is crucial to prevent damage to the material and to maintain the integrity of the assembly.

Overall, DIN7981 self-tapping screws have revolutionized the assembly process, offering improved efficiency, time savings, and versatility. By eliminating the need for pilot holes and providing excellent grip, these screws have become an indispensable tool in various industries. However, careful consideration must be given to size selection and torque control to ensure optimal performance. Incorporating DIN7981 self-tapping screws into assembly processes is undoubtedly a step towards enhanced productivity and overall assembly quality.